About us

At Milturn Precision, we specialise in precision engineering and advanced metal coating solutions. With a commitment to excellence and innovation, we deliver high-quality products and services tailored to meet the unique needs of our clients across various industries.

Precision Manufacturing

Applications for every industry

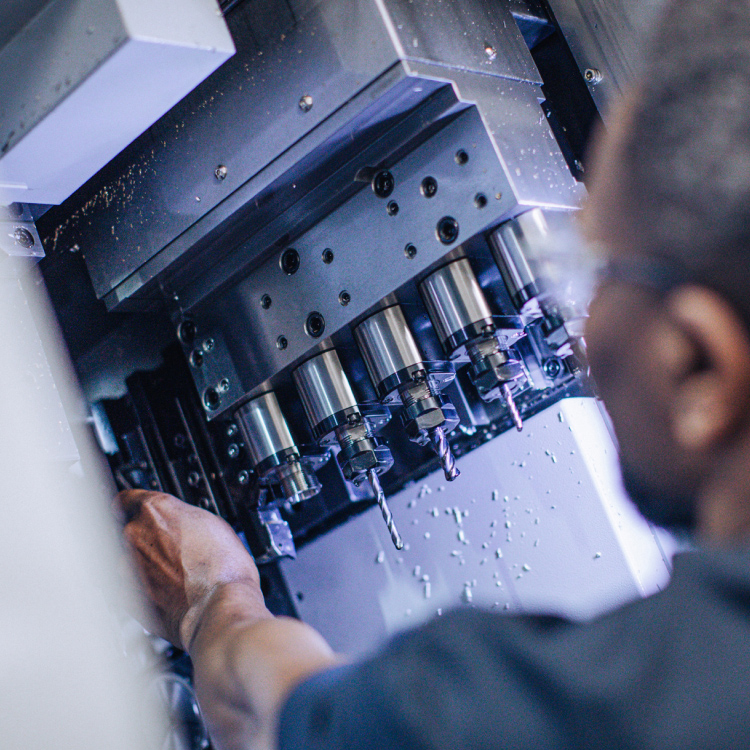

Precision Engineering

Utilising state-of-the-art technology and a team of skilled engineers, we provide precise and reliable engineering solutions that meet the highest standards of quality and performance.

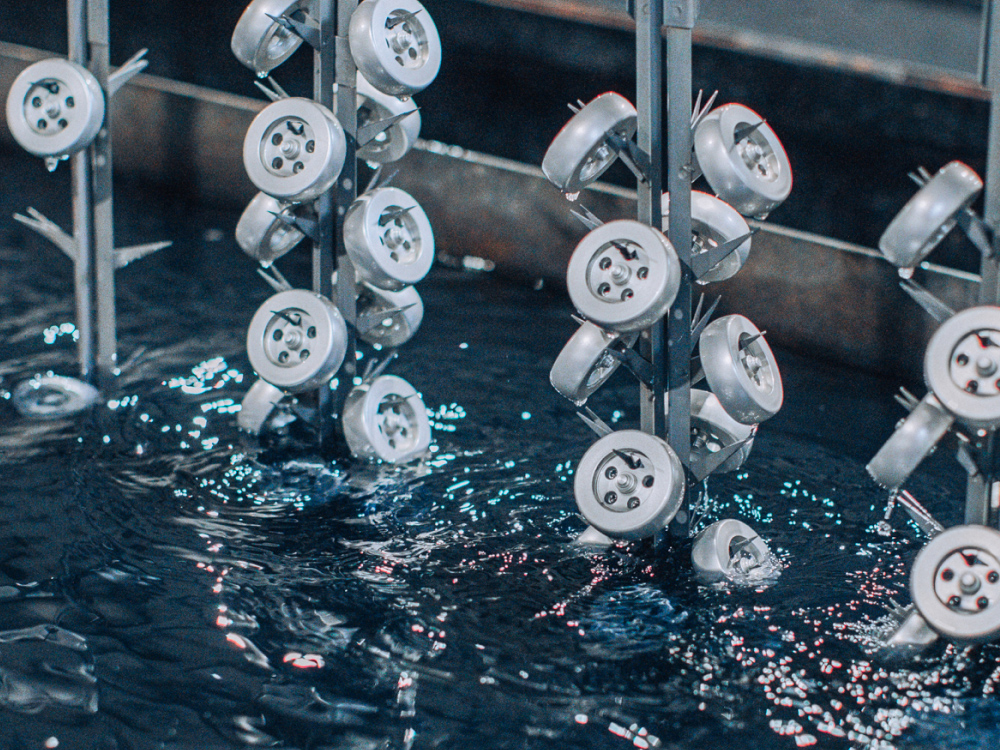

Metal Coating

Our advanced metal coating techniques ensure durability, corrosion resistance, and enhanced aesthetics for all your metal components.

Comprehensive Solutions

We offer a one-stop shop for machining and coating, providing full control over costs and deliveries under a single purchase order.

Our History

Milturn Precision is our new brand name. Two years ago, the Vision Engineering Group based in Surrey acquired Milturn Engineering, which included a machine shop and an anodising/coating company (formerly known as Bowfran).

The acquisition was part of our strategy to diversify into the subcontract machining market and streamline metal coating processes. CNC machines have been incorporated into our facility in Surrey, and a new anodising plant was commissioned and transferred to Measham in the North West Leicestershire district, with significant investments made across both sites.

Founded in 1958, Vision Engineering has grown from a small workshop to a leading provider of precision engineering and metal coating services. Today, we carry forward that legacy under the Milturn Precision name, focusing on exceptional machining and coating solutions.

OUR SERVICES

Additional Services

Consignment Stocking: Manufacture and hold stocks over agreed periods.

Free Delivery: Based on location.

International Shipping: Available on request (EU, US, and ROW).

Fast Tracking: Available upon request.

Precision Machining

High-quality machining services backed by advanced technology and expertise, delivering reliable and precise components for various industries.

Learn moreMetal Finishing

Our advanced coating solutions provide enhanced protection, longevity, and aesthetics for all your metal components.

Learn moreMeet our team

Rachel Rushton

Business Unit Manager

Steve Batsford

Business Development Manager

Chris Pope

Finishing Manager

Steve Mead

Group Operations Director

Scott Blackwell

Group Machine Shop Manager

John Marshall

Group QA Manager

Nathan Kinge

Group Manufacturing Engineer

Gary Olliver

Machine Shop Supervisor