High accuracy and quality anodising

With over 20 years of experience in the commercial anodising and coating aluminium Milturn Finishing Ltd has the knowledge and expertise to handle any project. Our team is highly skilled and has the experience necessary to deliver top-quality results.

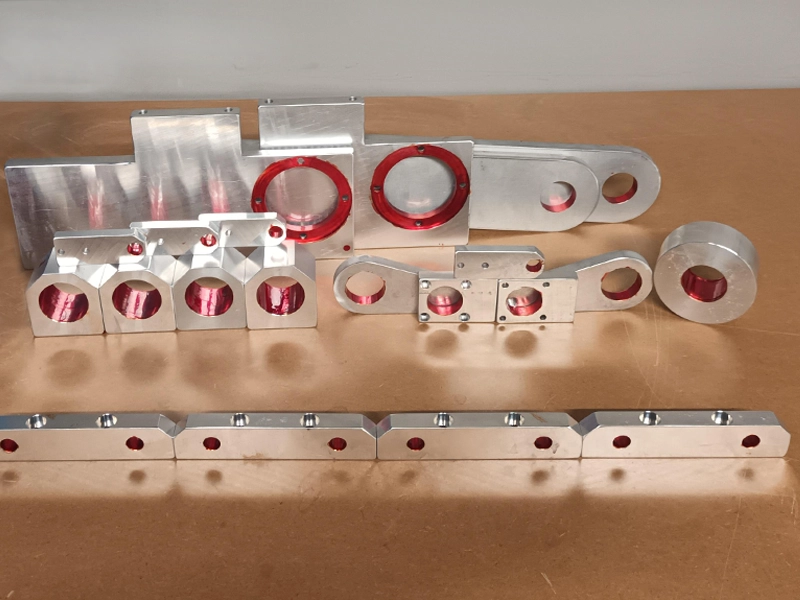

Our anodising facility is where we can anodise your components to suit your specific technical requirements. Select your preferred colour and finish standard to achieve the perfect degree of coating thickness.

What is Anodising?

Anodising is an electrochemical process that creates a protective oxide layer on the surface of a metal. This layer can improve the metal’s corrosion resistance, wear resistance, and electrical insulation properties. It can also be used to create decorative finishes.

The most common type of metal anodising is aluminium anodising. This process uses an electric current to convert the aluminium surface into aluminium oxide. The thickness of the oxide layer can be controlled by varying the voltage and time of the anodizing process.

Here at Milturn Finishing we offer a wide range of anodising services.

Sulphuric anodise

Best known as a cosmetic finish in that it has a luster finish to enhance the final product at the same time sealing the aluminium from the elements. It is the most common type of aluminium anodising and is used for a wide variety of applications, such as building materials, architectural fixtures, and automotive parts. Find out more.

Hard Anodise

For more hard wearing properties and usually has an etched surface for consistency.

The anodise here is used for applications that require high levels of durability, such as military equipment and aerospace components. Find out more

Hard Anodise PTFE Coated

Perfect for hard wearing component use where friction is critical, provides a coating of PTFE to standard hard anodize allowing moving components to move more freely whilst reducing the damage over time by such movement e.g. bearings. Find out more.

Benefits:

- Extreme wear resistance

- Superbly low friction

- Corrosion protection

- High temperature stability

- Easy cleaning